The cassegrain feed is described in more detail in the Proceedings of Microwave Update 2000,available from the ARRL.

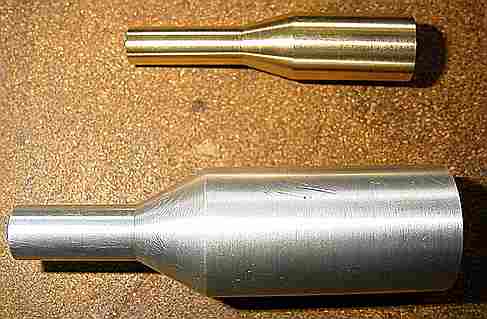

The photo left shows the complete setup, with David, then M5AFG (now M0VZT) in the background. He has an identical system except for his dish, which is smaller than the Procom one shown here. This photo clearly shows the rear mounted transceiver unit which is actually two large Eddystone diecast aluminium box bolted together. One box houses the 24GHz transverter while the other contains the 47GHz system. The cassegrain reflector on the dish is also homemade, the dimensions being calculated by means of an Excel spreadsheet which produces the necessary coordinates for a CNC lathe.